Our temperature sensors

by technology

From its origins, CORREGE has developed in-depth expertise in temperature measurement ranging from cryogenic applications to temperatures above 1500°C with continuous search for high quality and high precision products.

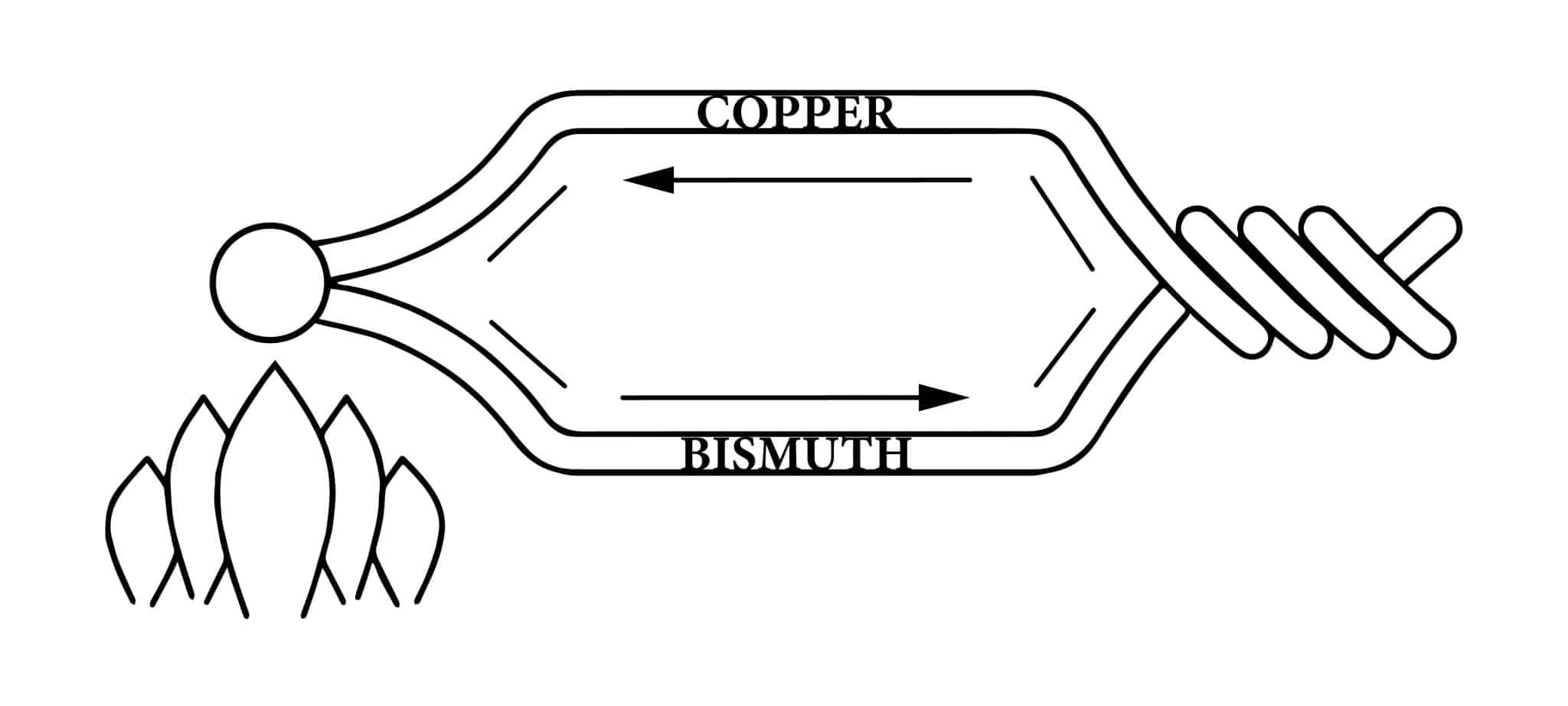

Thermocouples

A thermocouple consists essentially of a pair of dissimilar conductors welded or fused together at one end to form the “hot” or measuring junction with the free ends available for connection to the “cold” or reference junction. Thermocouples are reliable and robust solutions with a short response time for measuring temperature over a wide range and can be inserted in environments with high dimensional constraints. Finally, these robust products offer good resistance to vibrations. Our thermocouples are divided into 3 main families:

Thermocouples comply with the tolerance classes of the standard: EN 60584-2 – 07/1993

Technical advantages

- Geometric adaptability (bending)

- Small footprint (diameter up to <0.5mm)

- Good vibration resistance

- Short response times

Mineral Insulated Thermocouples

Mineral Insulated cables are commonly used for thermocouples Several combinations of metals can be used for the conductors insulated by this mineral powder, all encapsulated in a metal sheath.

This technology makes it possible to obtain robust and minimally intrusive products (small diameters) with unique shaping properties in order to adapt to geometric constraints. These products offer very good vibration resistance.

Mineral Insulated thermocouples can be terminated with a connector, a head or simply connected to a cable.

Thermocouples with metal or ceramic protectors.

Frequently used in the process industry, they respond perfectly to the aggressive environment or high temperatures.

The thermocouple will be encapsulated in a protector (or thermowell) which will be either a metal tube or a ceramic tube above 1100°C. The protector is fixed on a connection head.

This reinforced product ensures good rigidity and perfect tightness

Technical advantages

- TC protected from the aggressiveness of the environment.

- Resistance to very high temperatures

Cable thermocouples

Its simple design, without junctions, guarantees simple and effective implementation at a low cost.

Operating temperatures are limited to the temperature resistance of the cable.

They can be made up of one or two measuring elements depending on the needs: regulation, control, recording, etc. Different fixing systems are possible: fixed, removable or with a compression spring to ensure contact with the temperature measurement point.

Cable type depends on temperature range, tightness requirements, and compatibility with the sensor’s working environment.

Technical advantages

- Simplicity of junction free design

- Low cost

RTD sensors

RTD operate as a positive temperature coefficient device when a exitation voltage is applied to convert change in temperature to voltage signals by the measure of resistance.

RTD sensors or thermoprobes are temperature sensors whose sensitive element is encapsulated in protective sheaths of different types and dimensions, depending on the applications. Three types of sensing elements are used: in a thin layer on a ceramic substrate, wound on a ceramic support, or wound on glass.

RTD technology is more accurate and repeatable over time but the response time will be longer than the one of thermocouples and RTDs will be less adapted to temperatures above> 500°C.

Depending on the tolerance classes, standard accuracy varies from + 0.05 °C to + 0.30 °C, at 0°C. The precision also depends on the type of assembly – 2, 3 or 4 wires.

Our resistance probes will be divided into several families:

Technical advantages

- Simple designs

- Accuracy

- -253°C à + 500°C

- Normée selon IEC 60751

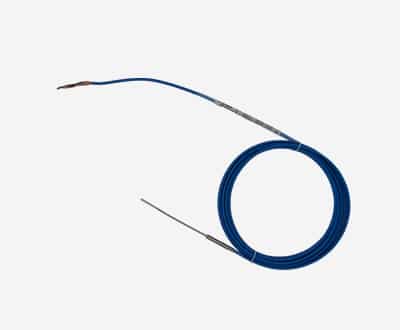

Cable type RTSs

Its design guarantees simple and effective implementation. The active part, generally small, is extended by a flexible cable of variable length, directly or indirectly connected via a non-removable junction box. Materials used are defined according to the applications. The probes are made up of 1 or 2 sensing elements depending on the needs: regulation, control, recording, etc.

Technical advantages

- Geometric bending

- Accuracy

- -253°C à + 500°C

- Normée selon IEC 60751

Mineral insulated cable Type RTDs

The active part, generally small – diameter of 2 to 5 mm – is extended by a stainless steel-sheathed mineral insulated cable. This connection allows bending of the sensor outside the active zone. Laser welding or brazing between the active zone and the MI cable guarantees perfect sealing. The connection is made via a cable, a connection head or a connector.

Technical advantages

- Robustness

- Accuracy

- -253°C à + 500°C

- Normée selon IEC 60751

Head type RTDs

These sensors are mainly used for temperature measurements in environments where the wired connection is separated from the temperature measurement zone (ovens, ovens, ducts, etc.). The active part in contact with the environment consists of a sensitive element in a metal tube. The connection is made on a terminal block or a transmitter mounted in a connection head.

Technical advantages

- Technical advantages

- Accuracy

- -253°C à + 500°C

- Normée selon IEC 60751

Connector type RTDs

The active part in contact with the environment consists of a sensitive element in a metal tube. Connection is made with a connector.

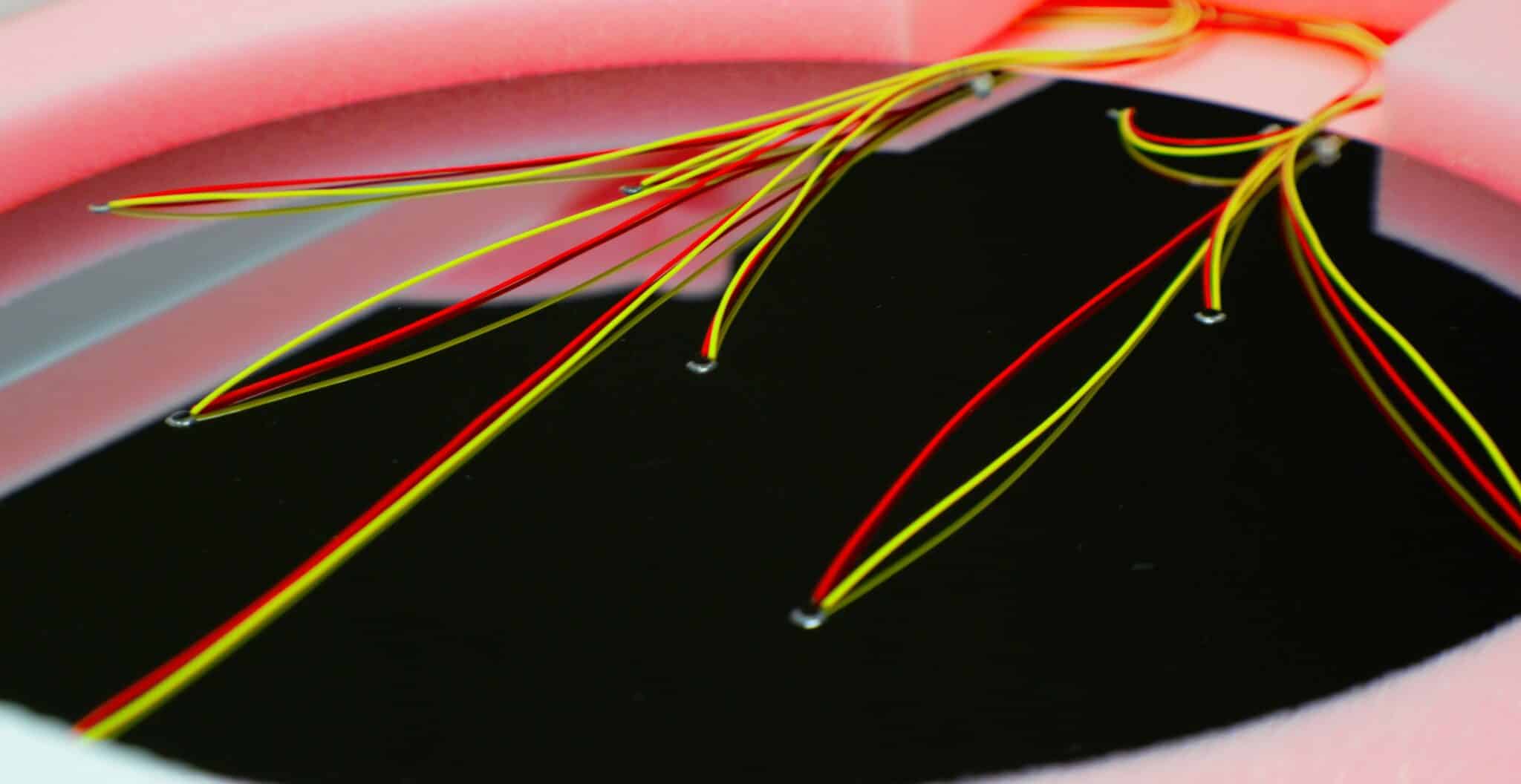

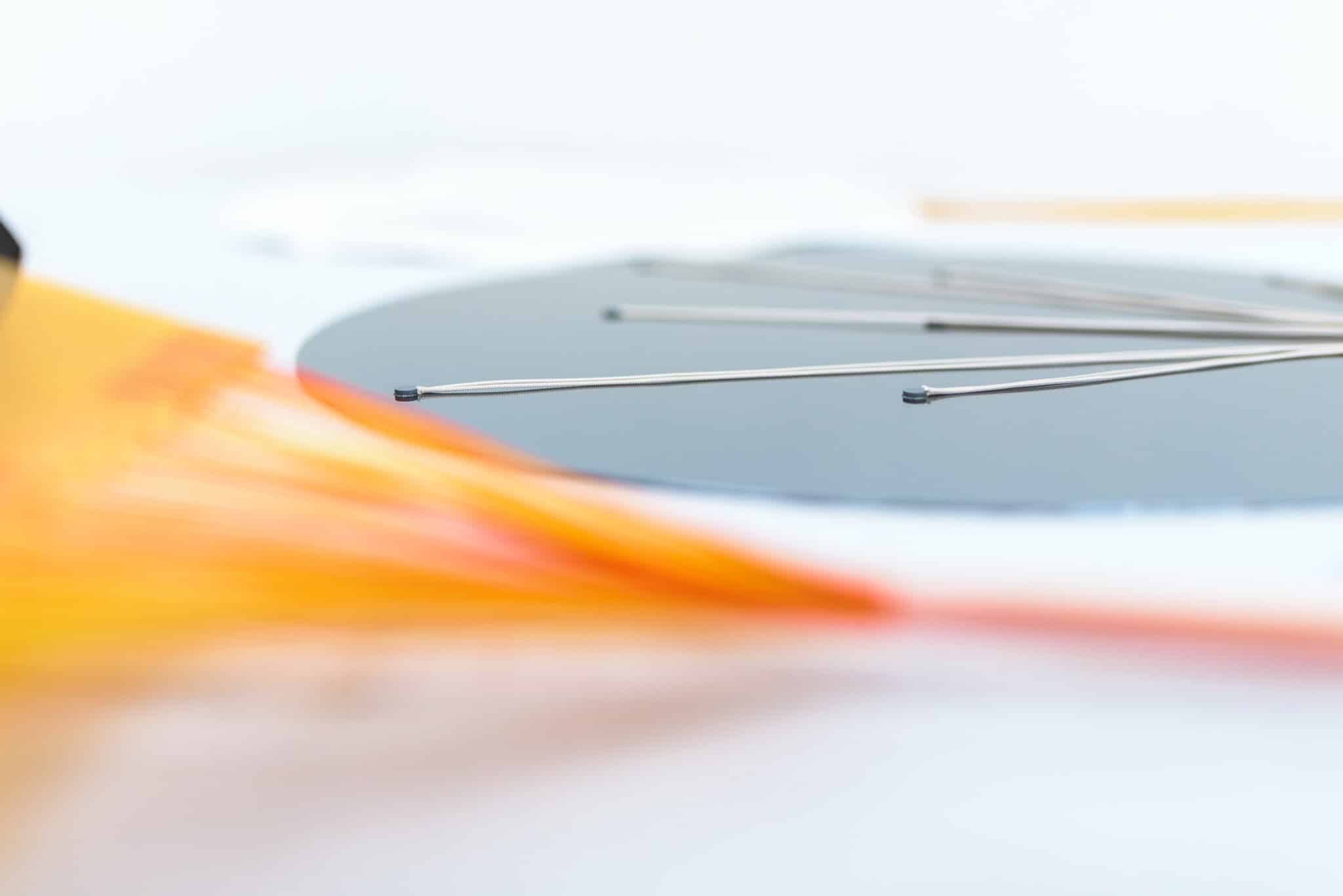

Instrumented TC Wafer

CORREGE has developed several specific temperature sensors used in the production of semiconductors such as instrumented wafers or spike and profile sensors. Our wafers instrumented with thermocouples make it possible to establish temperature maps of chuck zones where knowledge and control of the temperature on the surface of a Wafer are essential.

Instrumented Wafers sold under the CORREGE and Thermo Electric brands are used to calibrate equipment for Rapid Thermal Treatment (RTP), Rapid Thermal Annealing (RTA), Post Exposure Bake (PEB), Chemical Vapor Deposition ( CVD), Physical Vapor Deposition (PVD), ION implementations and other thermal processes.

We have the expertise to design and install our thermocouples on a wide range of substrates, including silicon, AlTiC, glass, ceramics and other materials, but also coated or patterned substrates.

Fill out our tailored quote form for your requirements:

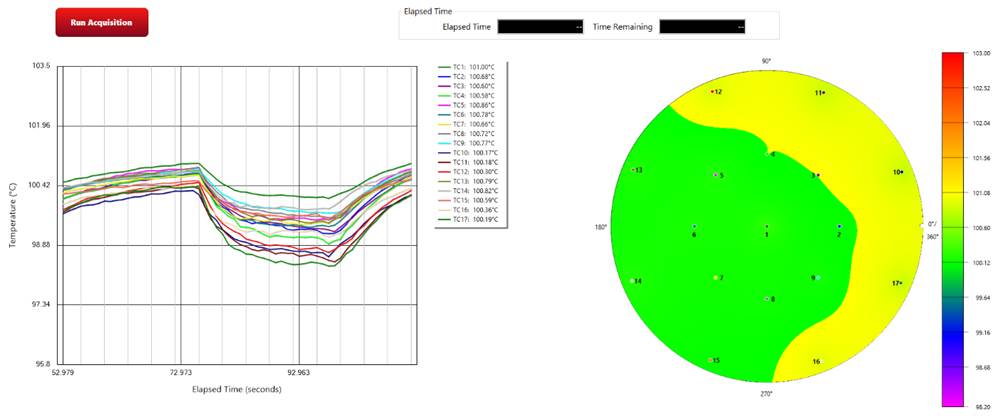

TEDAQ – Data acquisition system for instrumented wafers

A data acquisition system (TEDAQ) was developed to integrate the temperature measurement data recorded by our instrumented wafers.

Operating software has been developed to allow simple visualization of the temperature distribution in the chuck zone.

Our TEDAQ offers a simple, fully integrated solution compatible with Windows.

Instrumented TC Wafer

TC-350H | High Performance | -50°C to 350°C

TC-350D | Heavy Duty | -50°C to 350°C

TC-700H | High Performance | -50°C to 700°C

TC-700D | High Duty | -50°C to 700°C

TC-1200 | High Temperature | -50°C to 1 200°C

Nos Wafers utilisent les éléments de détection les plus petits possibles pour réduire la masse thermique et augmenter le temps de réponse de chaque capteur. The material used to make the sensors is carefully chosen for the highest possible accuracy and sensor-to-sensor uniformity.

This design finds application where knowing and controlling the temperature on the surface of a silicon wafer is critical. Unlike most manufacturers who integrate their sensors into the core of the wafer, our product focuses its measurement on the surface of the wafer where the most important processes occur. Using our product, you can expect faster and more accurate response times resulting from the most precise placement of sensing elements.

Instrumented wafers – Bounded design (up to 700°C)

Le BTC-700H offers a low profile and exact vertical alignment of a wafer pair to ensure quick and accurate response. This product responds to static and dynamic temperature changes occurring in typical wafer bonding processes.

The BTC700 is used in wafer bonding equipment where it is necessary to know and control the temperature uniformity on the surfaces of mating silicon wafers. MEMS, MOEMS, silicon-on-insulator (SOI), wafer-level packaging, and 3-dimensional chip stacking are the main technical categories where wafer bonding is used.

Spike & Profile Thermocouples

Spike & Profile thermocouples are essential in temperature control of semiconductor processes such as diffusion furnaces.

Thermo Electric and Correge have developed a wide range of expertise in precious metal thermocouples (Type B, Type S, Type R) and manufacture quality, state-of-the-art Spike & Profile sensor for the most rigourous processes in the semiconductor industry.

These multi-point oven sensors are used to manufacture wafers.

Accessories

Around temperature sensors CORREGE supports its customers by offering pyrometric components individually.

Câbles

Connecteurs

Doigts de gant

Têtes